What is the significance of Yield Strength (YS) in TMT?

Building Tomorrow? Then Build It Right

It is impossible to build a tomorrow, if the foundation of today is not built with integrity. If to construct a lasting legacy is your dream, then without a firm core, your investments, hard work and goodwill can come crashing down. The beauty of any structure elevates with time, only if they stand tall for the generations to come. And the only way to make your dream

project an enduring landmark, is to fortify its foundation with the right material and steel

Yield Strength & Elongation Is Important To Build It Right

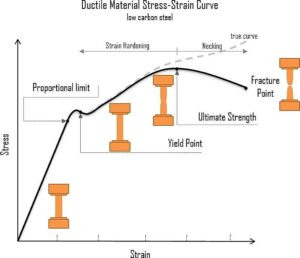

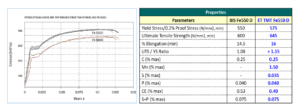

When TMT Steel Bar are being stressed in tension at relatively low levels, the applied stress is linearly proportional to the induced strain, i.e. elastic deformation both in Fe-500 D & Fe-550 D. Elastic deformation is non-permanent, i.e. the TMT Steel Bar returns to its original shape and size after the applied stress (load) is released. When the applied stress of TMT Steel Bar exceeds the elastic region, plastic deformation takes place, i.e. the applied stress is no longer proportional to the strain. The point where the nonlinearity of the stress-strain relationship begins is known as the proportional limit.

Yield stress (YS) is the stress level at the point where the TMT Steel Bar begins to have permanent deformation, i.e. yield point where the TMT Steel Bar no longer returns to its original shape and size after the release of the applied stress. However not all TMT Steel Bar will have a well-defined yield region. In the absence of a distinct yield point, a 0.2% offset is used to obtain an approximate yield point. The proportional limit and the yield point of TMT Steel Bar are close to one another on a stress-strain curve, but they each have a different representation and thus do not corresponds to the same point on the curve.

Ductility means the ability of material to easily deform and adapt as it is put under stress with tensile load within a construction unit. Ductility of the TMT Bar mainly counts on the elongation. How much elasticity the material has form its original length to the point of collapse. Ductility is the ability of the TMT Bar to be elongated without loosing its strength. Ductility in TMT Bar is more important because it determines how much it can bend as per the construction requirement. Therefore, Elongation is one of the most important factor before you choose to buy TMT Bar.

Value of yield stress is important in the construction of structure such that the structures are able to perform in the elastic region under normal servicing condition. However when faced with unexpected impact loads such as explosions, fires or natural disasters such as earthquakes etc. the plastic region of the TMT Steel Bar becomes crucial as a large portion of the energy being absorbed by the TMT Steel Bar under such circumstances is mainly contributed by the plastic region.

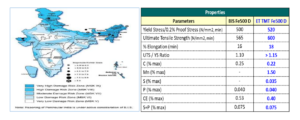

1.Fe-500 D TMT Bars:

2.Fe-550 D TMT Bars:

- Fe-500 D and Fe-550 D are some of the better-quality TMT steel bars that are available in the market today. Due to their strength and ductility, they are the go-to choice for infrastructure, as they make the construction resistant to earthquake.