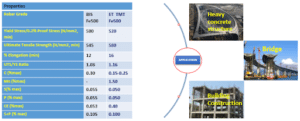

ET TMT’s Fe-500 & Fe-550D Bars: Know Their Properties & Applications

While constructing heavyweight structures, it is important to choose TMT bars that can bear the load of the building. Not many bars are as strong and durable as to resist a structure’s immense pressure. The TMT bars you use for a load-bearing building have to be produced the right way to stand the test of time. At ET TMT, we believe in building it right so that the TMT bars you purchase from us can help your landmarks last longer.

ET TMT’s refined TMT steel bars available in grades Fe-500 and Fe-550D are the perfect choice for load-bearing structures. They come in a wide size range from 8MM to 40MM. ET TMT- an unbreakable bond with cement, extremely strong, high strength, ensuring low level of sulphur & phosphorus with redefining steel making technology.

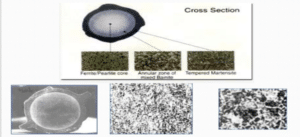

Overall microstructure of ET TMT Bar consists of tempered martensitic, acicular Ferrite (AF) along with ferrite & pearlite in the weld deposit. This type of microstructure produces best combination of strength & bendability.

Latest THERMEX quenching technology to produce ET TMT Rebar of the highest standard. During thermo mechanical treatment tempered martensitic structure formed at surface portion & the microstructure of weld deposits consists of acicular Ferrite (AF) along with ferrite & pearlite formed at core portion. The fine grained randomly oriented AF gives higher strength (YS, UTS).

TMT- an

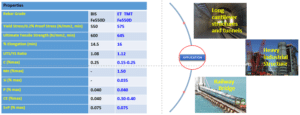

ET TMT Steel manufacture with modern steel making technique, maintain close range carbon content (0.17% -0.21%) & carbon equivalent (0.32%-0.38%).

ET TMT produced killed steel use ladle refining furnace technology, very low % gas content (nitrogen<110 ppm, hydrogen<2 ppm).

ET TMT Fe-500

- Superior Quality ⇔ TMT process, means quenching, self-tempering & atmospheric cooling monitor with automation system for achieving proper microstructure and desire mechanical properties great weldability, strength and bendability (Higher % of Elongation & Higher UTS/YS ratio).

- Superior Ductility ⇔ Rebar’s can undergo plastic deformations to a large extent without necking & thus resist ultimate breakage.

- Close dimensional tolerance ⇔ Mass /meter on the negative side of the specified tolerance on weighted average basis.

- Better bond strength ⇔ high energy absorption capacity, absorb the stress easily & to a much higher extent without any danger of sudden &catastrophic rupture

.ET TMT Fe-550D

- Homogeneous steel quality with highly control chemistry with low level sulphur & phosphorus ⇔ Steel is made using BF/DRI→IF→LRF→Concast Route

- High Strength & ductility due to fine grain multiphase composite structure ⇔ Rebar’s are manufacture by using Thermex technology for heat treatment & consistent maintaining of Equalizing & finishing temperature.

- Superior earthquake resistance quality due to high capability of absorbing energy ⇔ meets UTS/YS ratio & high % of elongation

- Reduction of steel consumption ⇔ For constructing the same structure 7.5% reinforcement saving. Since Fe-550 D are stronger than other rebar the overall steel consumption come down leading to cost saving.

- Build up stronger construction ⇔ Provide Higher Strength to resist natural calamity & increasing Impact Toughness.

At ET TMT, we believe in stringent quality control from the start of the manufacturing process till the finished product is prepared. When you want to construct load-bearing structures that last over years together, choose ET TMT Fe-500 and Fe-550D grade TMT steel bars for a stress-free construction experience. If you want to build it right, choose ET TMT.