Fusion Bonded Epoxy Coated TMT Bars & Its Significance

Why we prefer Fusion Bonded Epoxy Coated TMT Bars rather than normal TMT Bar?

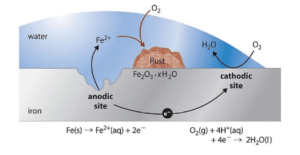

We prefer Fusion Bonded Epoxy Coated TMT bar because it prevent TMT Bar from Corrosion.Corrosion is a galvanic process by which metals deteriorate through oxidation usually but not always to their oxides. Various metals subject to corrosion, iron is by far the most important commercially.

When iron corrodes, it forms a red-brown hydrated metal oxide (Fe2O3⋅xH2OFe2O3⋅xH2O),commonly known as rust that does not provide a tight protective film. Instead, the rust continually flakes off to expose a fresh metal surface vulnerable to reaction with oxygen and water. Because both oxygen and water are required for rust to form, an iron nail immersed in deoxygenated water will not rust even over a period of several weeks.

What is Fusion Bonded Epoxy Coating?

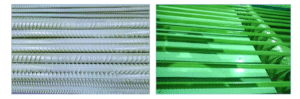

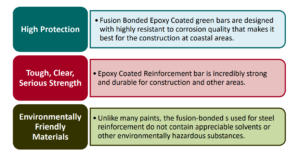

Commonly known as FBE coating, Fusion Bonded Epoxy Coating is used to protect concrete, TMT bars, steel pipes, piping connections and more from corrosion. Due to the protective film, epoxy coated TMT bars last longer and add to the quality of the construction.

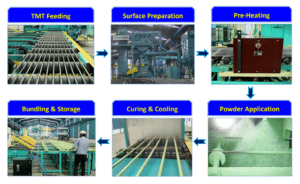

How Is Fusion Bonded Epoxy Applied?

At normal atmospheric temperature, Epoxy is in powder form. The powder is applied to clean hot steel bars, and is left to be hardened after undergoing various chemical processes.

Different test methods for checking the quality of Epoxy Coated Bar

Apart from the manufacturing process, there are several test methods to confirm the quality of the Epoxy Coated TMT Bar, which are given below

Significance of Fusion Bonded Epoxy Coatings

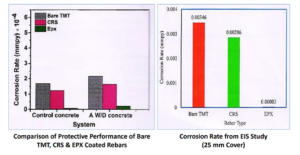

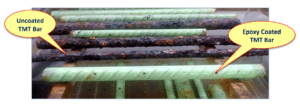

Comparison of Uncoated & Coated Bars in Coastal Salty and Humid Atmosphere Created in Laboratory

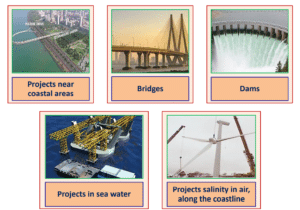

Application of Fusion Bonded Epoxy Coatings

Epoxy Coated TMT Bars are used in concrete subjected to corrosive conditions. These may include exposure to deicing salts or marine environments.

Behavior of Uncoated Bars in Coastal Areas after Due Course of Time

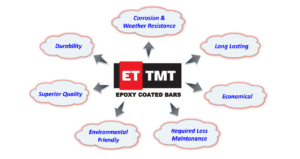

Advantages of Fusion Bonded Epoxy Coated TMT Bars

Fusion Bonded Epoxy Coated TMT Bars Corrosion Performance Evaluation by CSIR-CECRI, Karaikudi (SSP 13/19-Interim Report)

CSIR-CECRI (Council of Scientific and Industrial Research – Central Electro Chemical Research Institute)

The concrete specimens were exposed to corrosion testing yard located in Mandapam unit of CSIR-CECRI situated near Rameshwaram, Tamilnadu, India. The coastal area in Rameshwaram is considered to have the World’s second most corrosive environment next to Florida.

Comparison of Protective Performance: