ET CRS TMT

BARS

ET CRS TMT Bars are corrosion-resistant, high-yield strength, ductile

and bendable bars made from high-quality sponge iron and copper,

chromium & phosphorous vanadium additives.

Widely trusted for reliability in reinforced concrete structure, these bars

deliver durable structures to meet industry standards of quality and

longevity.

and bendable bars made from high-quality sponge iron and copper,

chromium & phosphorous vanadium additives.

Widely trusted for reliability in reinforced concrete structure, these bars

deliver durable structures to meet industry standards of quality and

longevity.

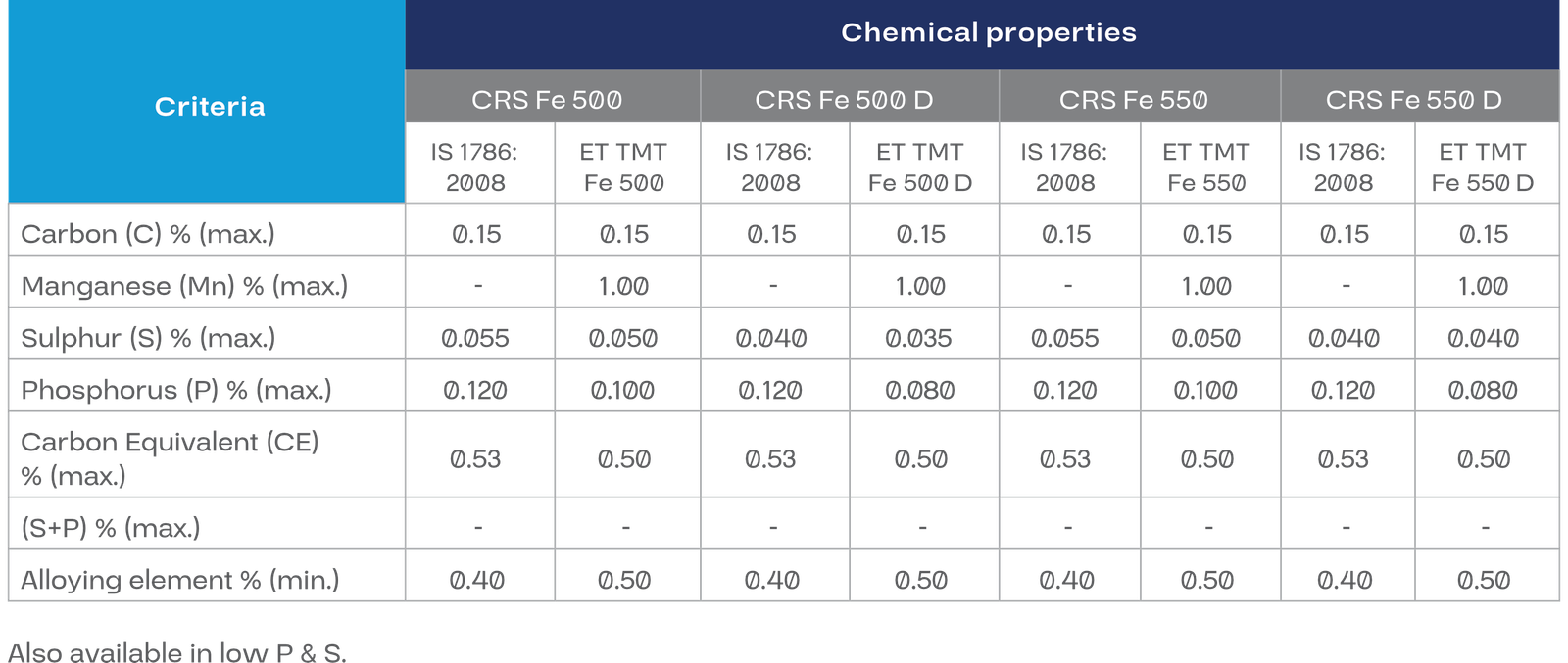

ET CRS TMT Bars are corrosion-resistant, high-yield strength, ductile and bendable bars made from

high-quality sponge iron and copper, chromium

& phosphorous vanadium additives.

Widely trusted for reliability in reinforced concrete structure, these bars deliver durable structures to meet industry standards of quality and longevity.

Widely trusted for reliability in reinforced concrete structure, these bars deliver durable structures to meet industry standards of quality and longevity.

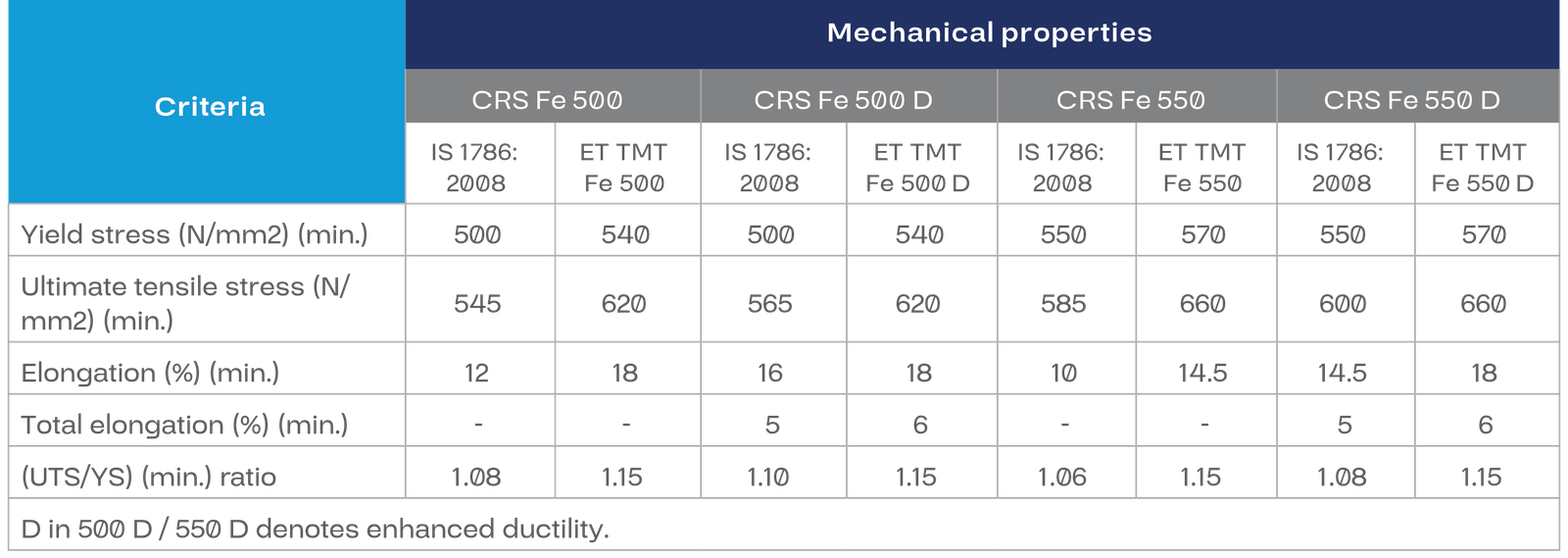

Available Grades

CRS Fe 500

CRS Fe 500 D

CRS Fe 550

CRS Fe 550 D

CRS Fe 600

Advantages

High-quality sponge iron ensures high-quality CRS

(Corrosion-resistant steel).

(Corrosion-resistant steel).

High-quality sponge iron ensures high-quality CRS (Corrosion-resistant steel).

Copper, chromium & phosphorous vanadium additives

enhance corrosion resistance.

Copper, chromium & phosphorous vanadium additives enhance corrosion resistance.

Superior pitting corrosion resistance ensures a

long life for structures.

Superior pitting corrosion resistance ensures a long life for structures.

High ductility enables steel to undergo permanent

changes without rupturing.

High ductility enables steel to undergo permanent changes without rupturing.

Superior bendability.

Superior bendability.

ET CRS TMT BARS

Properties

Have Questions? Call us Now

Sales: +91 8238079223

Need Support? Write to us

salestmt@electrotherm.com