EPOXY-COATING

Well-Equipped Manufacturing Facility

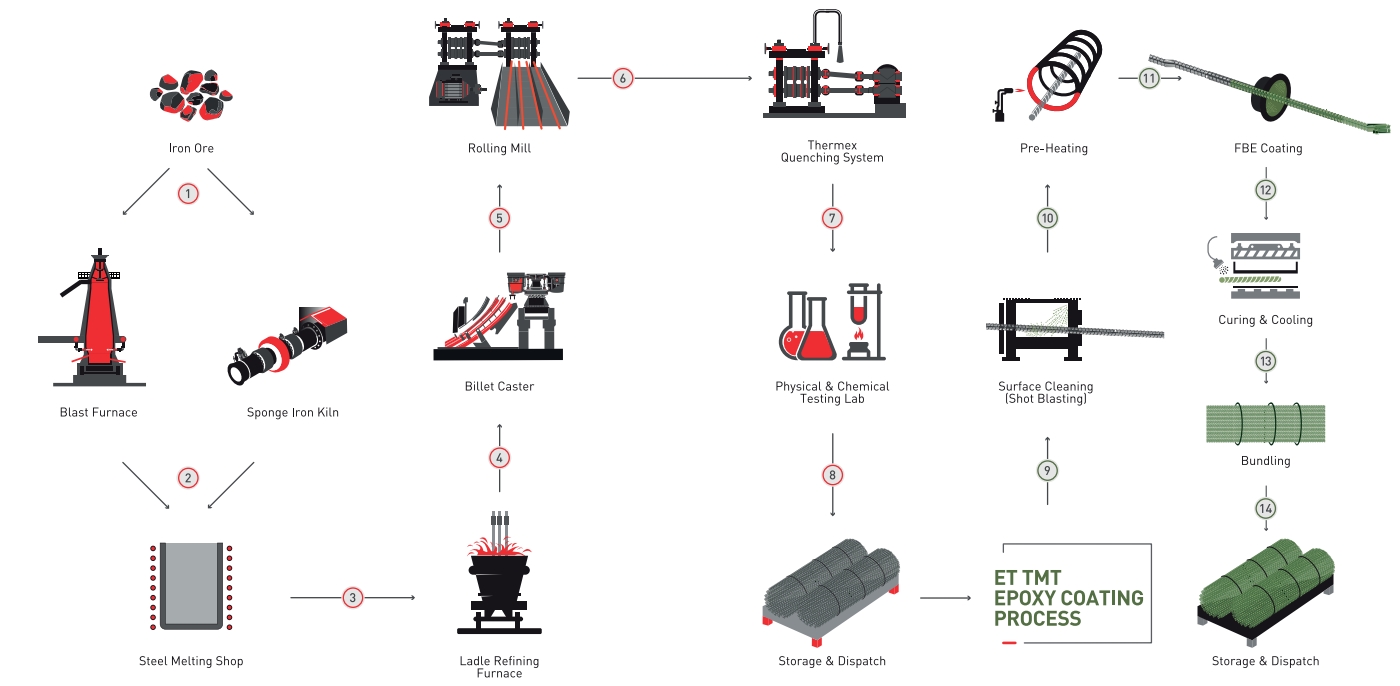

ET TMT’s fully automatic, integrated, state-of-the-art 5.0 LTPA TMT bar manufacturing facility in Kutch, Gujarat, has set a new bar for quality. Equipped with a capacity for end-to-end manufacturing of TMT bars, the facility also has NABL-approved physical and chemical testing laboratories. The unit has a captive power plant to ensure uninterrupted power supply.

Fully integrated sponge

iron kilns.

Induction melting

furnaces.

Ladle refining

furnaces

6/11 continuous

casting machines

Continuous high-speed

rolling mill

Three-stage thermo-

mechanical treatment

Epoxy coating

plant

Spectrometry

facility

Cutting & bending

facility

Blast furnace &

sinter plant

Ductile iron pipe plant

and utilities

NABL-approved physical

and chemical testing

MADE TO PERFECTION

Focus on Quality

ET Epoxy-Coated TMT bars walk down a path

with stringent quality norms. Quality is controlled diligently from ingredients and processes to testing to ensure perfect and uniform results.

High-quality of ingredients

High-quality sponge iron BIS-certified billet steel is produced

in-house. Using 100% iron ore ensures an extremely low level of tramp elements.

Cutting-edge technology/processes

ET TMT bars are manufactured with fully automated processes to ensure consistent quality and precision. Sponge iron and liquid metal undergo a long process of purification, strengthening and other enhancements with automated machines. more…

Stringent testing and QA

Protocol-driven testing and QA is carried out in NABL-accredited in-house physical and chemical laboratories.

Have a longer life due to superior pitting corrosion resistance.

Possess high strength to

resist applied forces.

Epoxy Coated TMT 500 D, Fe 550, 550 D and Fe 600 have

higher strength and ductility values than those specified by

IS 13620:1993 standards.

THE METHOD OF

BUILDING IT RIGHT

From the blog

Revolutionizing Reinforcement: Exploring the Advantages of Epoxy Coated TMT Bars

[psac_post_slider show_date="false" show_author="false" show_comments="false" show_category="false" autoplay="false"]